University Wollongong

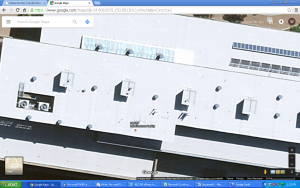

AECOM in Sydney, NSW, Australia worked with the Wollongong University on their new SMART Infrastructure Facility and installed 13 EP900 ecoPOWERs on the roof. (The EP900 is the largest of the ecoPOWER family with a 42 inch diameter turbine on top of a huge 36 inch throat and a motor that pulls 5,885 CFM at just 273 watts). You can click on the picture for a larger view and you will see the 13 round ecoPOWER hybrid rooftop ventilators clearly.

Mark Stephenson is the facilities manager and the head of the team that created the design for the building. Mark explained the purpose of the Edmonds hybrid ventilators and the operation of the system. He says that the air conditioning is a multimode system which, when turned on, checks for 3 items – 1. Wind not high. 2. Rain not falling. 3. outside air temp over 18 and under 24 C. If true, then the system opens motorized louvered windows to use the natural cooling of the hybrid vents and watches the interior temperature for 20 minutes. If stable, this continues. If not, the EP900s are powered to increase air flow. Temperature is watched for another 20 minutes. If stable, this continues. If the temperature goes high, then the windows are closed, the motors turned off and regular air conditioning is started.

He also shared a favorite rule of thumb he uses there. He says that if the thermostat is set to 26 C then the cost of running air conditioning is optimum – but some people say that is too hot. Setting it just 1 degree less or 25 C raises the total energy cost a huge 10%! 24 C is 20%. The most important outcome of the Wollongong case is that the system uses free gravity and wind ventilation when first turned on, then uses low cost motorized ventilation to further delay the activation of the air conditioning resulting in a dramatic decrease in energy cost.